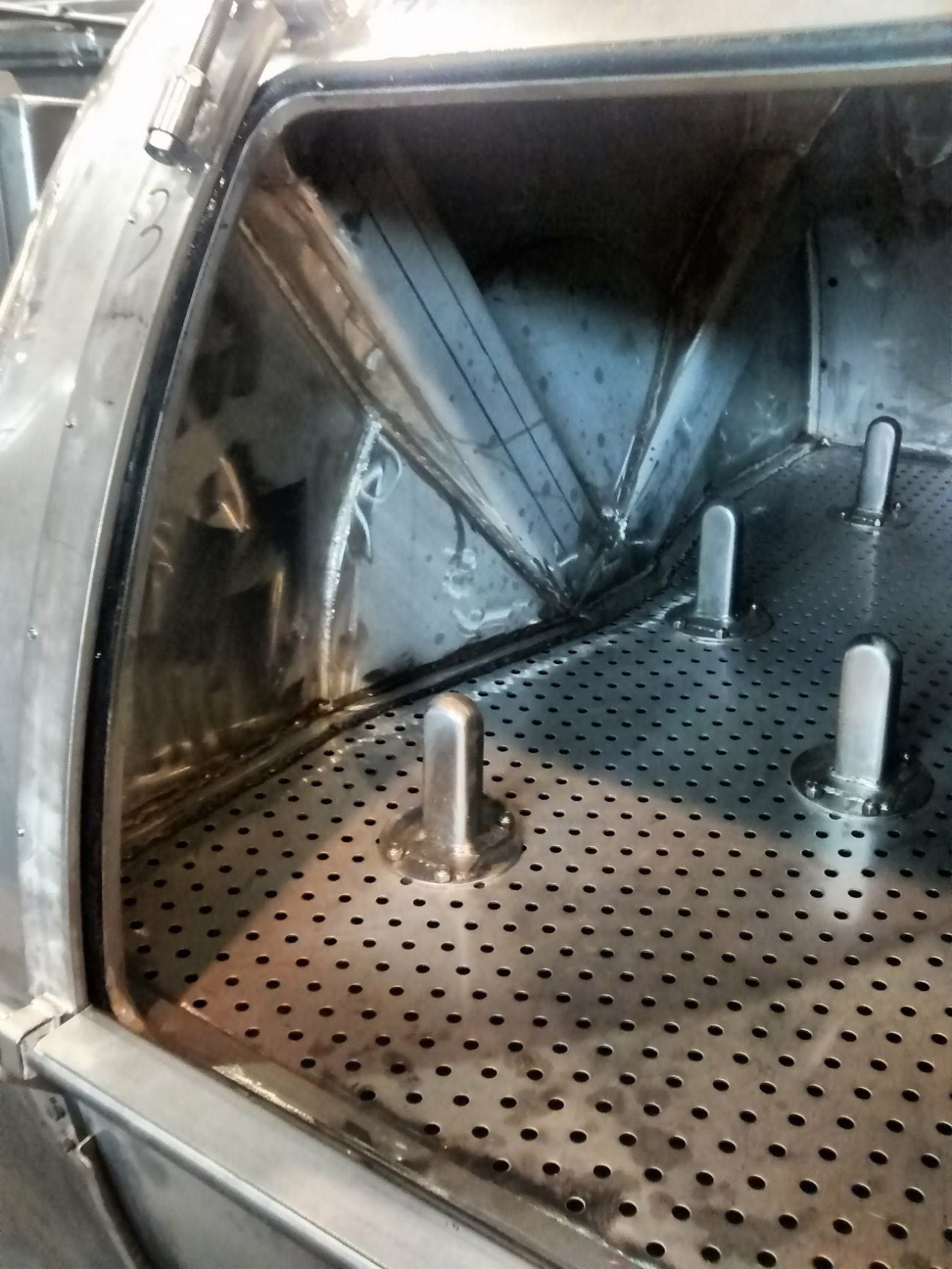

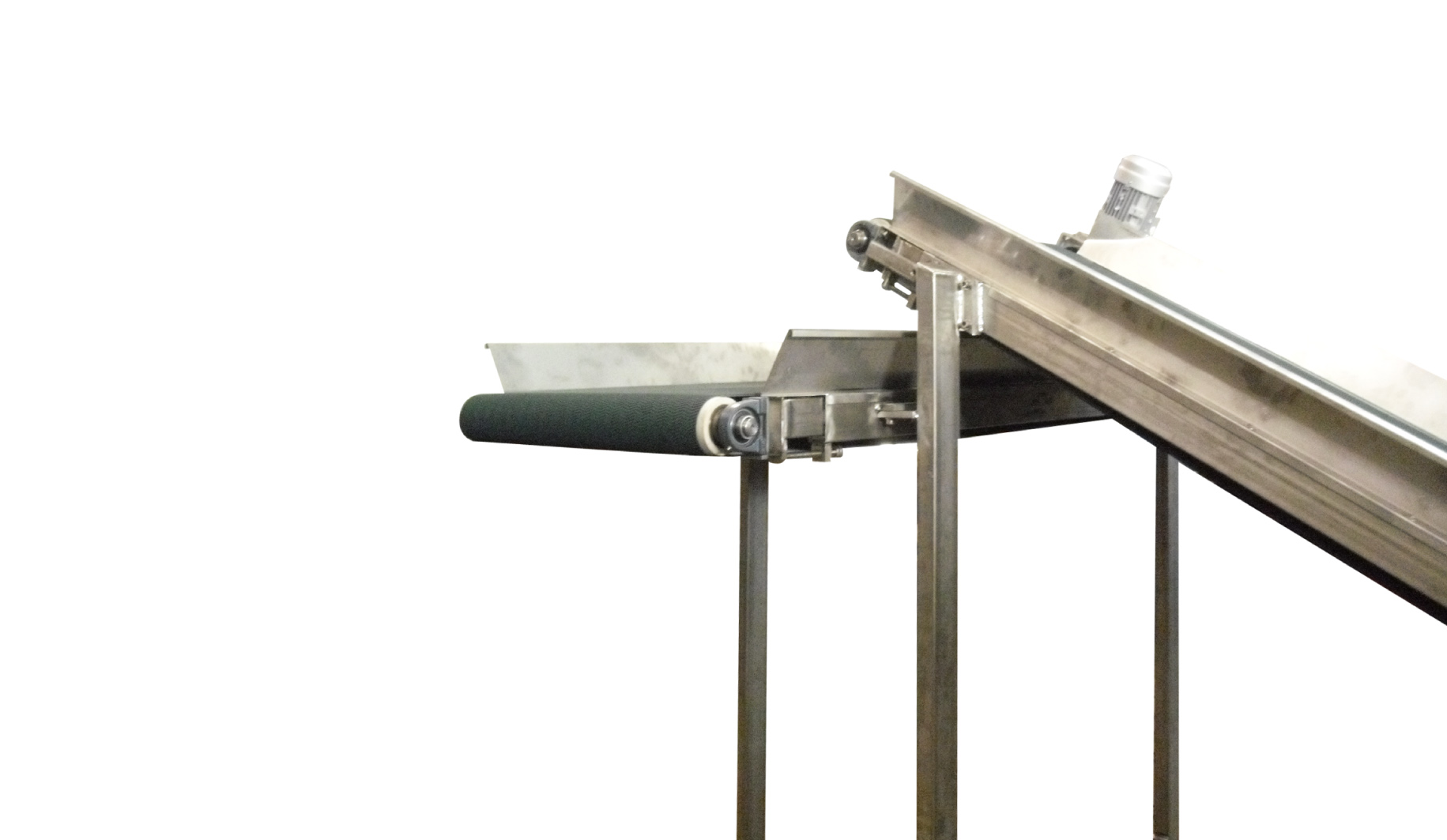

Buffing machines are designed for buffing and smoothing all leathers continuously. Using an appropriate abrasive paper wound around a cylinder, leathers are smoothed by the buffing process and come out with a uniform and smooth finish. The heavy structure of OPTIMA buffing machines allows the use of thick rollers and therefore more powerful motors that make the machine more performing and guarantees greater stability over time. The model OPTIMA, in accordance with the needs of the various processes, is successfully used to buff different kind of leathers and other materials.

Working width (mm): 800, 1200, 1500, 1800, 2200, 2400, 3200, 3400